PRODUCTS

Existing and Custom Products for your R&D Needs

Engineered Filtration Solutions has numerous pre-designed systems that will address your separations challenges. Our line of pre-designed skids provides an array of flowrates providing you with the tangential flow processing you need without the need for ground-up design.

Of course, we will design and build membrane custom separation systems to meet your requirements as well. Once we know your requirements, we will work with your engineering team to provide the best possible solution to your separations issue.

Our pre-designed systems include high pressure reverse osmosis, ultrafilters, osmotically assisted reverse osmosis and our bench scale RO system, Test Track. EFS also has an available line of small ion exchange and carbon filtration systems.

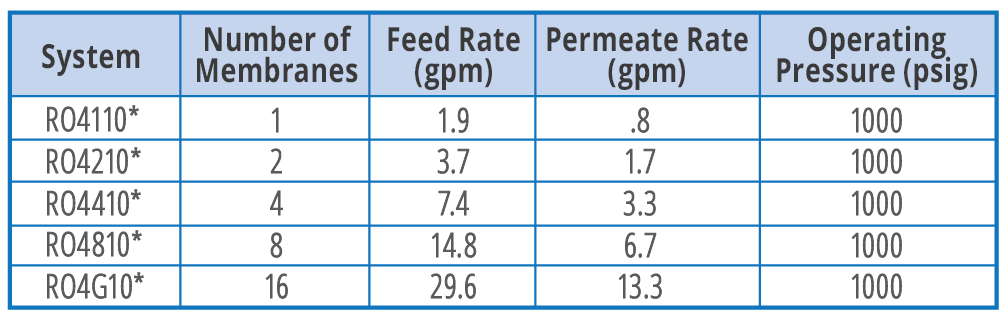

High Pressure Reverse Osmosis

Engineered Filtration Solutions specializes in 4” reverse osmosis (RO) systems for pilot, demonstration and small production applications. The systems feature Veolia seawater membranes and can operate as high rejection RO or nanofilters. Each system operates with a variable frequency drive (VFD) on the high pressure pump to allow for pilot and experimental trials as various flowrates and membrane fluxes.

Engineered Filtration Solutions also offers a variety of brackish water system with operating pressures between 90 and 300 psig. Our channel partner Veolia Water Technologies & Solutions has designed their PROflex LT and standard PROflex lines to cost effectively meet the low pressure RO requirements for any application.

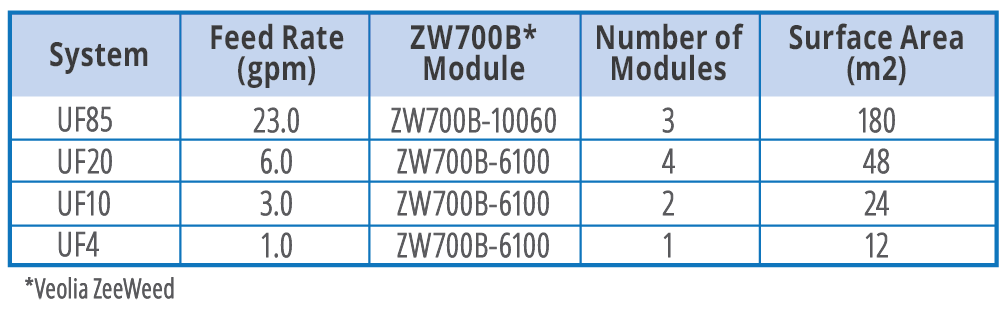

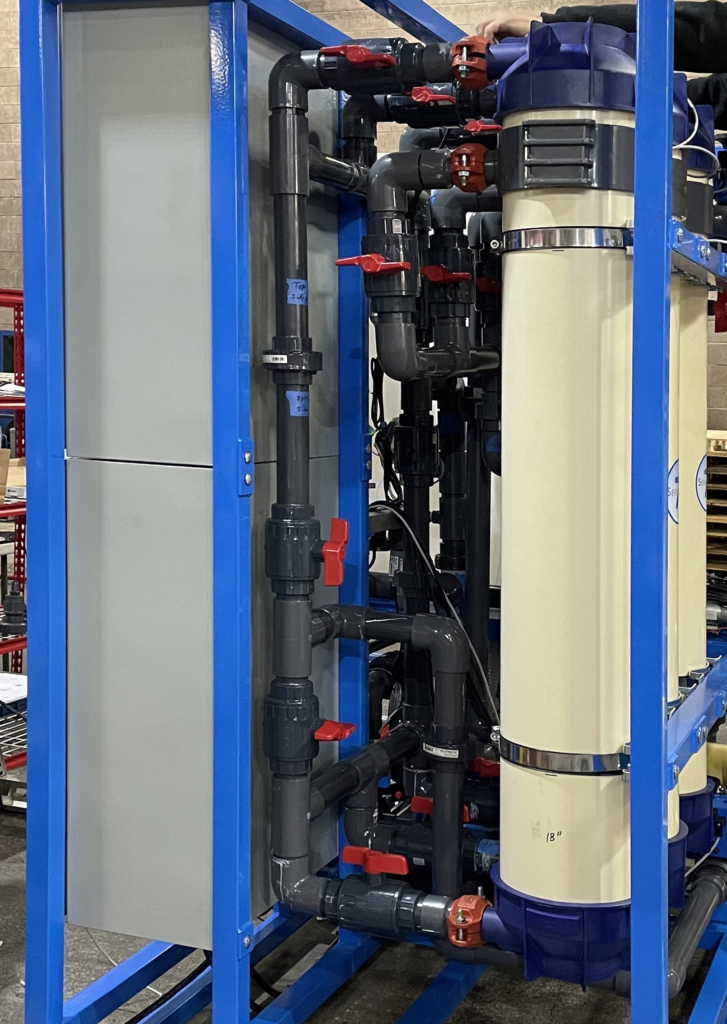

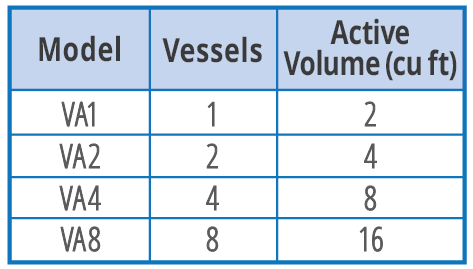

Ultrafilters

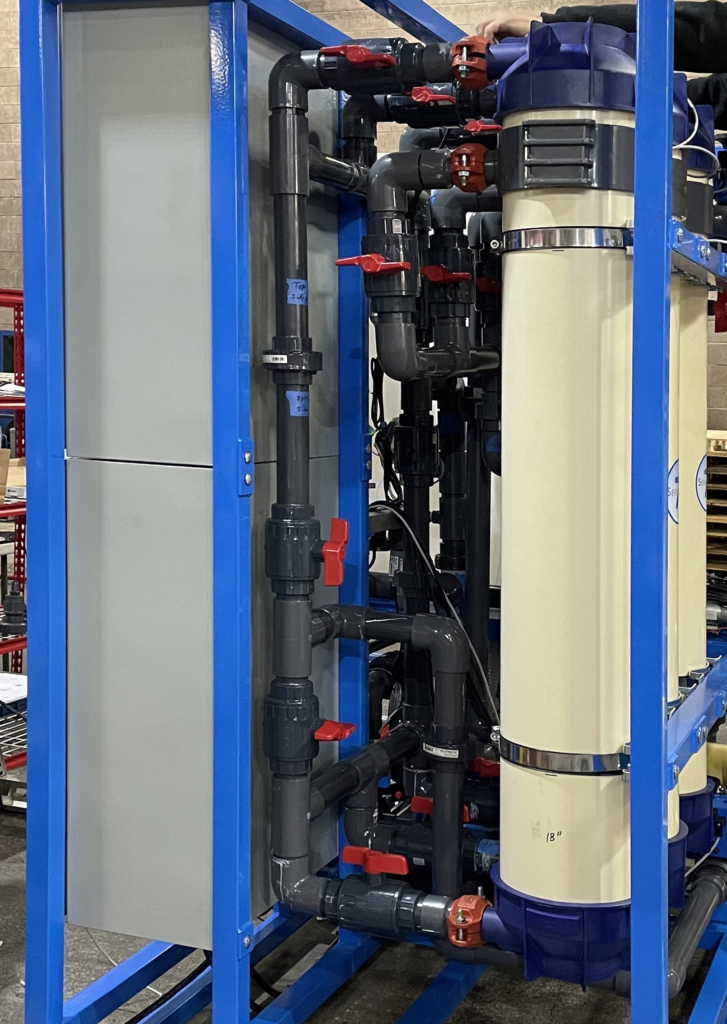

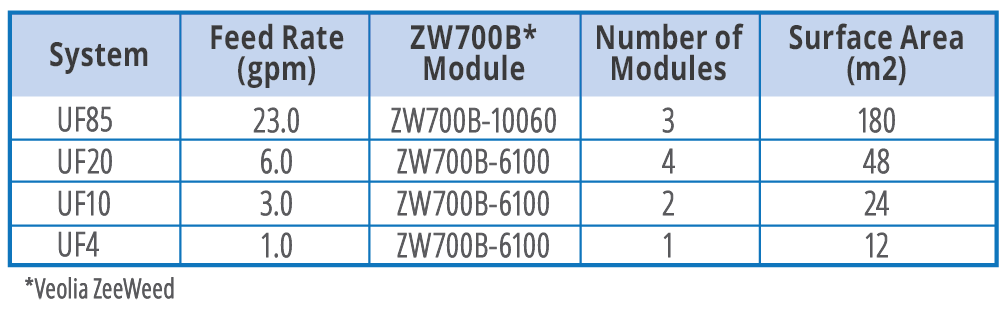

The EFS pre-designed ultrafilters feature the Veolia ZeeWeed 700B (ZW700B) inside-out ultrafilter modules with back-pulse cleaning. The nominal pore diameter of the membrane will be 0.02 µm with a theoretical 100K – 150K Dalton molecular weight cut off (MWCO). Design flux and recovery are 30 LMH and 90% respectively.

The pumps will be driven by VFDs. Process control and data logging will be accomplished with a Siemens S7-1200 PLC (or similar) equipped with an HMI. Each system will have high and low voltage panels. Process flow paths will be controlled by solenoid valves or electrically actuated ball valves, depending on the system size. The control algorithms will allow for flexibility in permeate flow rate, cross flow velocity, overall recovery, and cleaning cycle details.

Ultrafilters

The EFS pre-designed ultrafilters feature the Veolia ZeeWeed 700B (ZW700B) inside-out ultrafilter modules with back-pulse cleaning. The nominal pore diameter of the membrane will be 0.02 µm with a theoretical 100K – 150K Dalton molecular weight cut off (MWCO). Design flux and recovery are 30 LMH and 90% respectively.

The pumps will be driven by VFDs. Process control and data logging will be accomplished with a Siemens S7-1200 PLC (or similar) equipped with an HMI. Each system will have high and low voltage panels. Process flow paths will be controlled by solenoid valves or electrically actuated ball valves, depending on the system size. The control algorithms will allow for flexibility in permeate flow rate, cross flow velocity, overall recovery, and cleaning cycle details.

Osmotically Assisted Reverse Osmosis

The EFS Osmotically Assisted Reverse Osmosis (OARO) brine concentrator can provide salt rejection and brine concentration far beyond traditional RO. While traditional reverse osmosis processes are limited to treating brines to an osmotic pressure below the membrane housing rated pressure, in OARO, the osmotic pressure difference across a membrane is reduced by introducing a dilute brine to the permeate side of a unique hollow fiber membrane, allowing OARO to increase permeate production, further reducing concentrate flow rate and increasing its salt concentration.

The OARO can be integral to a zero liquid discharge (ZLD) operation or those where the downstream thermal concentration systems are cost prohibitive. As with the RO, the permeate is very desirable process water. The concentrate is very high in dissolved solids, very close to the point where material precipitates out of solution. As such, the OARO minimizes the capital requirements for a thermal concentration.

Engineered Filtration Solutions currently offers OARO-1, capable of a trial-scale feed rate of 2 gpm with a brine concentration demonstrated at over 10%.

Test Track

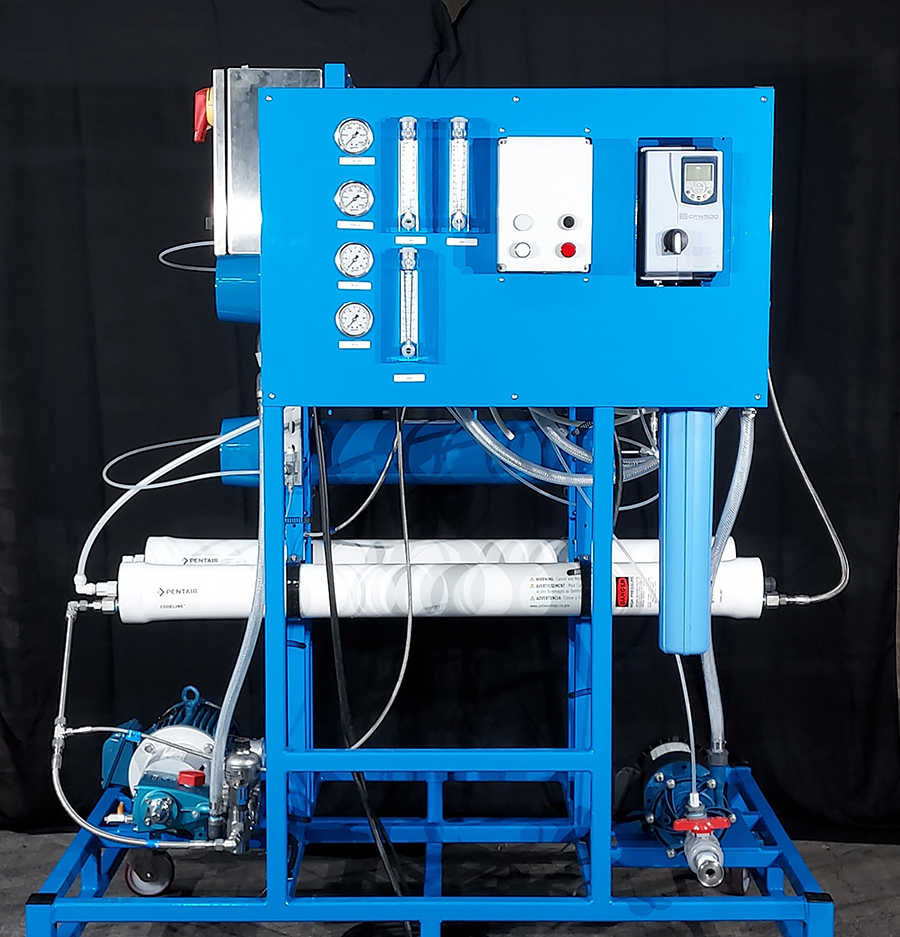

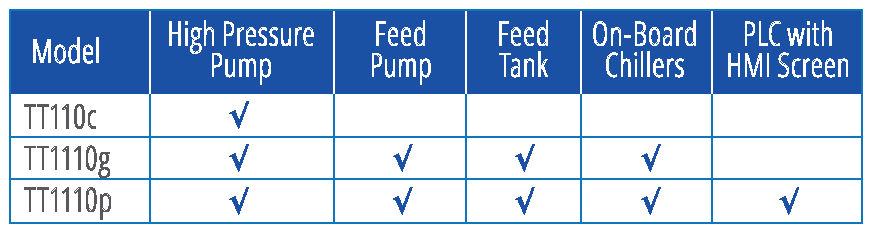

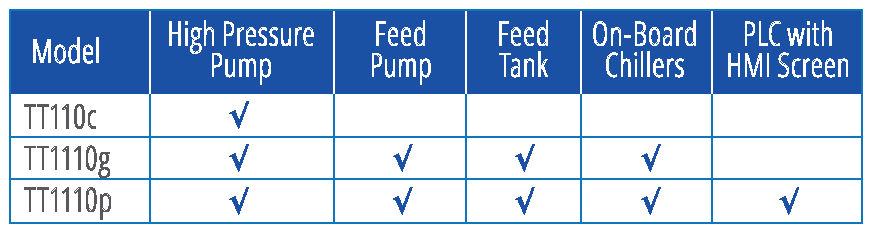

The EFS 1110TT Targeted Filtration System (Test Track) is an RO capable of testing various spiral wound membranes on a bench-scale in the ionic and molecular RO ranges as well as Ultrafilter pore sizes. Each Test Track model will provide the follow trial possibilities:

- Produce permeate at a rate up to 10 liters per hour

- Operate as a high pressure seawater RO processing fluids with TDS levels ranging from 3,500- 35,000 ppm

- Operate as a low pressure brackish water RO processing fluids with TDS levels ranging from 300 – 500 ppm

- Allow for trials filtration trials with spiral-wound membranes of varying molecular weight cut off (MWCO).

Features may vary by model

Test Track

The EFS 1110TT Targeted Filtration System (Test Track) is an RO capable of testing various spiral wound membranes on a bench-scale in the ionic and molecular RO ranges as well as Ultrafilter pore sizes. Each Test Track model will provide the follow trial possibilities:

- Produce permeate at a rate up to 10 liters per hour

- Operate as a high pressure seawater RO processing fluids with TDS levels ranging from 3,500- 35,000 ppm

- Operate as a low pressure brackish water RO processing fluids with TDS levels ranging from 300 – 500 ppm

- Allow for trials filtration trials with spiral-wound membranes of varying molecular weight cut off (MWCO).

Features may vary by model

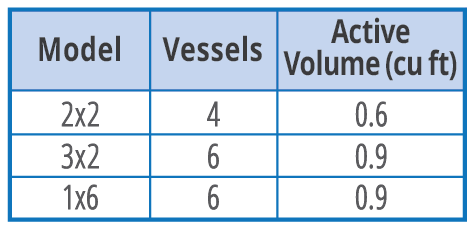

2×3 Carbon System

Ion Exchange and carbon filtration

EFS has readily available systems for small ion exchange operations or carbon block/activated carbon filtration

ION EXCHANGE CANNISTER

CARBON SYSTEMS

Existing Product Line

Engineered Filtration Solution can provide the system you need for your pilot, demonstration or small production filtration needs. Our pre-designed systems are field tested and have proved robust and effective in a variety of operating conditions.

EFS is currently working on new designs for Ultra high pressure RO and contactor membrane chemisorption along with new offerings for OARO, ultrafilter, RO and electrodialysis/bipolar electrodialysis (ED/BPED). If you are in need of systems in this technology arena, please contact EFS with your requirements.