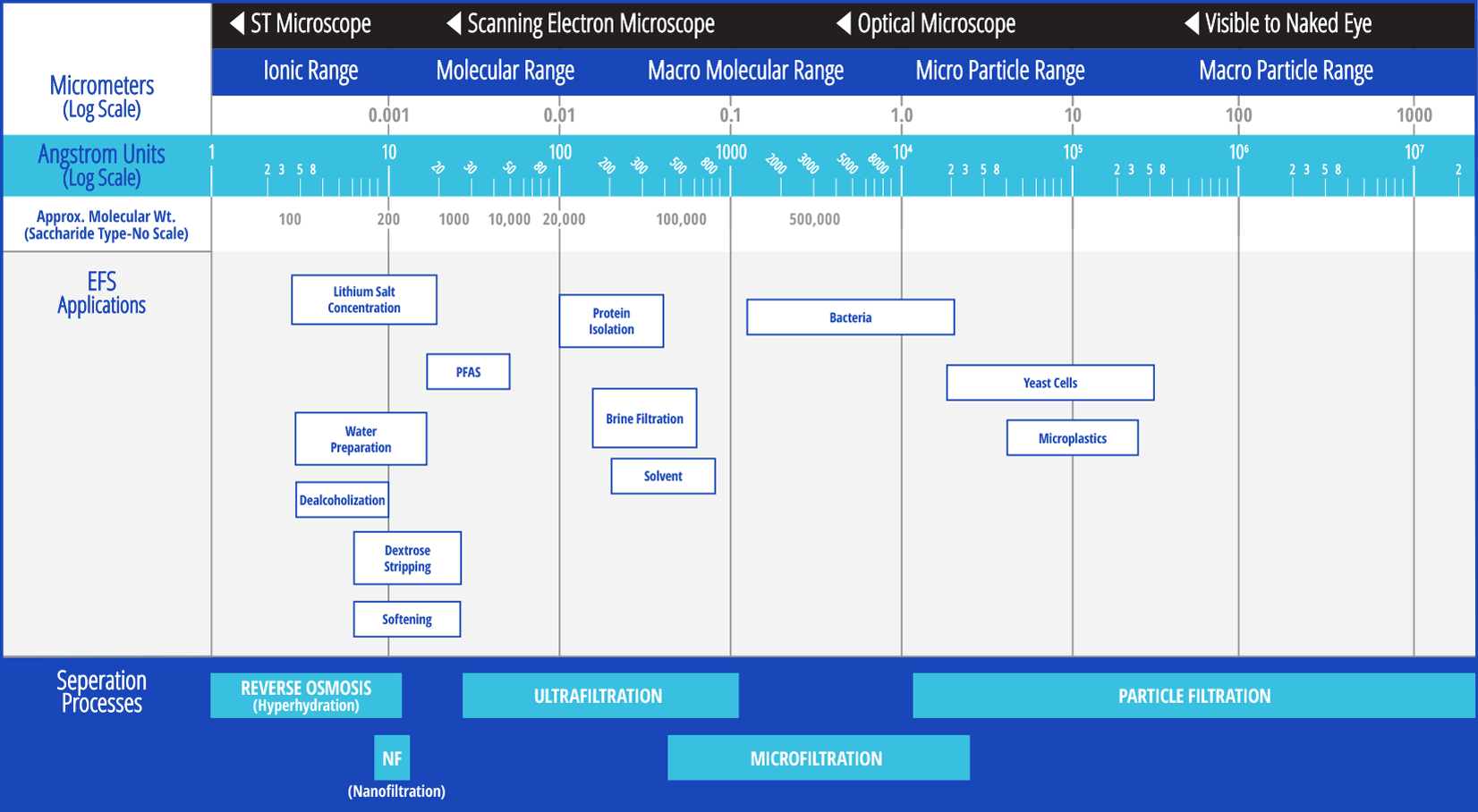

TECHNOLOGY

Details about Engineered Filtration Solutions technologies:

Ultrafilter (UF)

Ultrafiltration is often the first step to aqueous solution processing.

The Veolia ZeeWeed modules contain a series of long, thin polymer tubes or fibers. Water is drawn through the tubes by a pump, leaving the solid material behind. The system is regularly “back pulsed” with clean permeate to knock solids off the fiber surface. The ZW700B has an “inside-out” flow pattern, for solutions high in small particle size suspended solids. The ZW1500 has an “outside-in” flow pattern, making it more suitable for low suspended solids load, but larger particle size.

Nanofiltration (NF)

Nanofiltration processes low TSS feed with membranes in the range of 250 molecular weight cut off (MWCO). The NF acts as a water softener, removing the ions that scale downstream equipment. These are the divalent ions of calcium and magnesium.

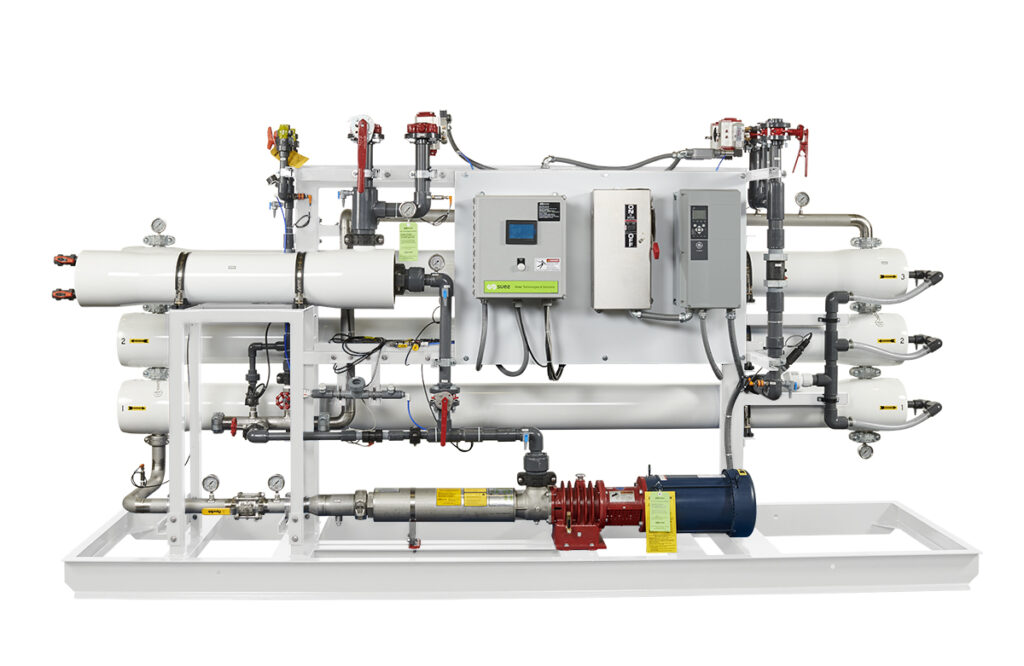

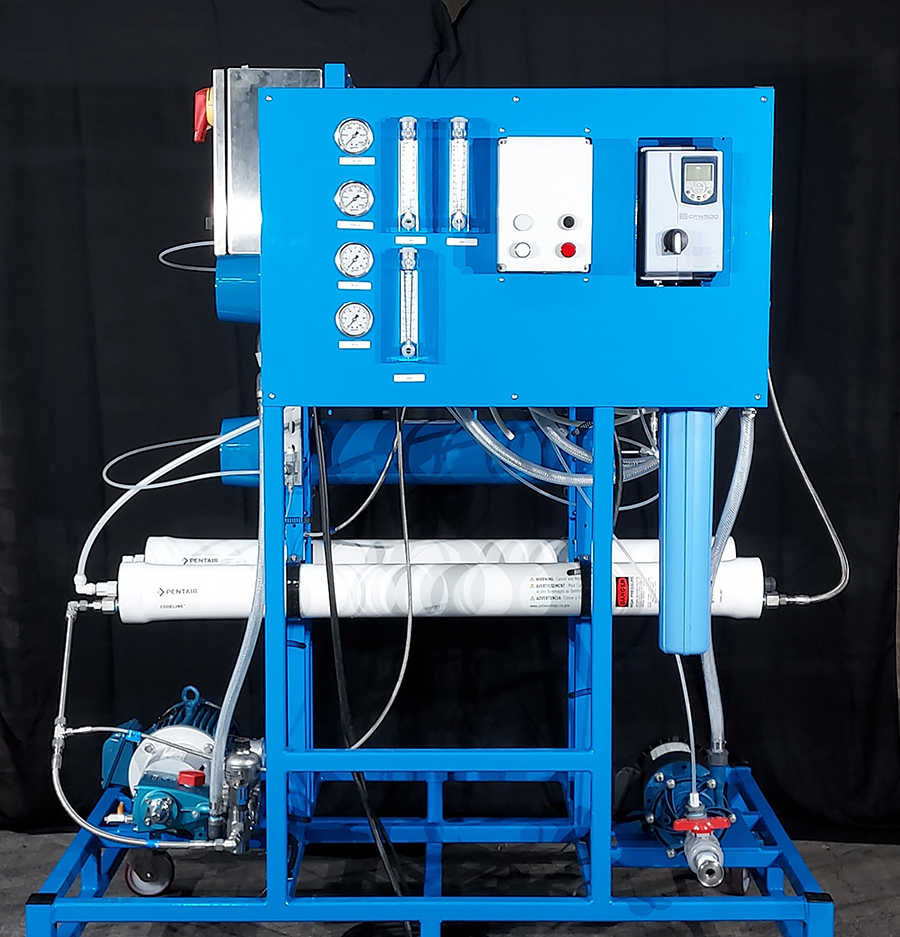

Reverse Osmosis (RO)

Reverse Osmosis (RO) utilizes membranes with a 100 MWCO and can effectively remove up to 99% of the incoming total dissolved solids (TDS). RO permeate can be recycled as water for many industrial uses. Depending on the composition of the original wastewater, the concentration from the RO can represent 4% of the treated water volume.

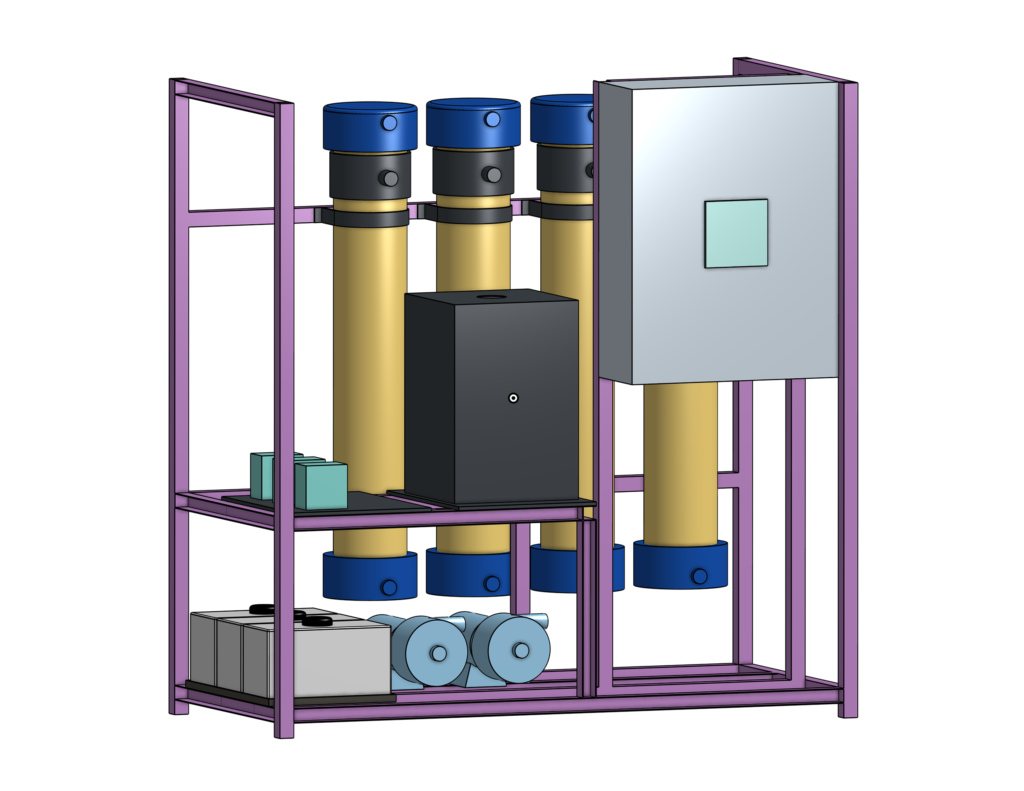

Osmotically Assisted Reverse Osmosis

The EFS Osmotically Assisted Reverse Osmosis (OARO) can further concentrate brine. While traditional reverse osmosis processes are limited to treating brines to an osmotic pressure below the membrane housing rated pressure, in OARO, the osmotic pressure difference across a membrane is reduced by introducing a dilute brine to the permeate side of a hollow fiber membrane, allowing OARO to increase permeate production, further reducing concentrate flow rate and increasing its salt concentration.

The OARO can be integral to a zero liquid discharge (ZLD) operation or critical in reducing brine volume to downstream systems. As with the RO, the permeate is very desirable process water and can be employed in numerous ways. The concentrate is very high in dissolved solids, very close to the point where material precipitates out of solution. As such, the OARO minimizes the capital requirements for a crystallizer or the expense of off-site disposal.